Sapphire Screen Protector for iPhone 16 Series

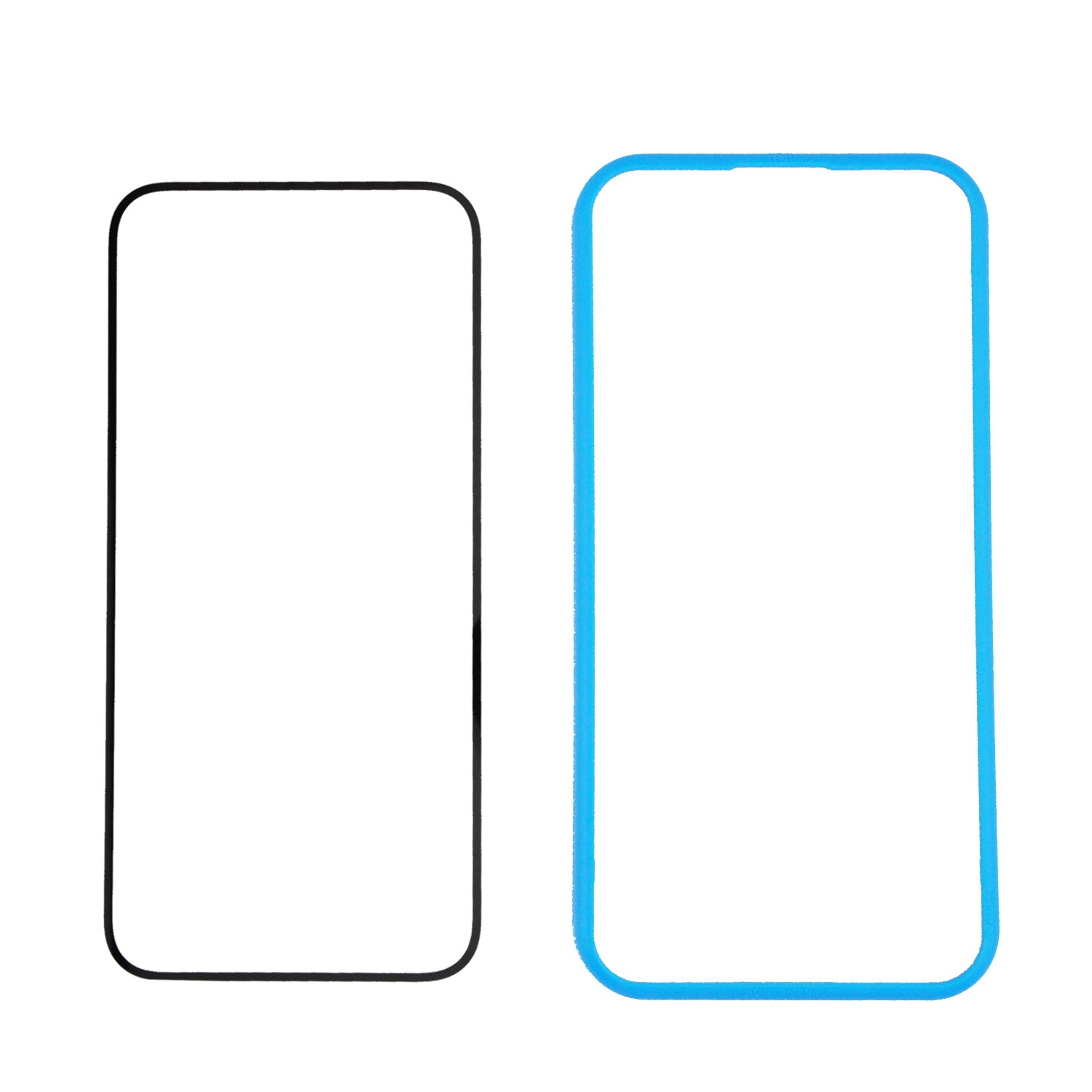

Not Edge-to-Edge: iPhone 16 series will have 2.5d curved screen, but we are not able to make sapphire with curved edges, the screen protector will only cover the flat area of the screen. No worries about that because the black bezel won't overlap with the display.

Pairs well with

In stock! Ships within 1-2 business days.

90-day risk-free trial

2-Year Warranty

Complimentary shipping & returns

Sapphire Screen Protector for iPhone 16 Series

Why You Might Wanna Switch To Sapphire

Our smartphones are the most frequently touched items in our daily lives, so it's essential to choose a screen protector that offers the best feel and experience. Our sapphire screen protector is smoother and cooler to the touch, making every swipe and tap more enjoyable.

What Makes Sapphire Special

Only a diamond is more scratch-resistant.

Material

Our sapphire crystal is crafted using the Heat Exchanger Method, a technology that Apple attempted but couldn't fully master. Each crystal takes 21 days to grow and an additional 9 days to cut and polish, making our screen protector one of the most premium - and expensive - in the world.

Scratch Resistance

The most durable screen protector available, rated 9 on the Mohs hardness scale for ultimate scratch resistance.

Touch

Sapphire has a dielectric constant of 9.4 to 11.5, about 1.3 times higher than tempered glass, which enhances touch sensitivity significantly. Sapphire is also smoother and conducts heat faster than glass, giving you a noticeable difference from the very first touch.

Ultra-Thin Design

With an ultra-thin design measuring just 0.23mm, it keeps your iPhone's sleek profile intact while providing strong protection against scratches.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.